20t Axle Load Ballast Prestressed Concrete Railway Sleepers

In the background is a track with concrete ties. A railroad tie, crosstie ( American English ), railway tie ( Canadian English) or railway sleeper ( Australian and British English) is a rectangular support for the rails in railroad tracks. Generally laid perpendicular to the rails, ties transfer loads to the track ballast and subgrade, hold the.

Cross sections of B70 prestressed concrete sleepers. (a) Longitudinal... Download Scientific

The wayatogaa.awo TO EACH CUSTOmER HIS OwN SLEEpER In the age of individualization, RAIL.ONE as the leading pro- vider of concrete sleepers and track systems has developed a strategy that focuses on individual customer requirements and general project constraints in all application areas.

Concrete Railway Sleeper Supply Concrete Products Boodle's Concrete

Quick Explanation of Key Points Concrete sleepers offer many advantages compared to traditional timber sleepers. They are durable, require minimal maintenance, and can be designed in various shapes and sizes to suit different applications. What are Concrete Sleepers?

Econ Antri Limited

Description Specifications Type B70 concrete sleepers are the simplest way to achieve your finished track. The main advantage of these sleepers lies in their great flexibility.

Concrete Sleepers in 60lb track VGR Civil Blog

The average timber sleeper weighs around 160lb-250lb, whereas an equivalent sleeper made of concrete could weigh anything up to 800lb. This means that wooden sleepers are quicker and easier to install initially and require little to no specialist equipment or vehicles for maintenance, which means cost-savings for rail operators.

The Ghan Concrete Railway Sleepers Traditional Design

A concrete sleeper ( British English) or concrete tie ( American English) is a type of railway sleeper or railroad tie made out of steel reinforced concrete . History In 1877, Joseph Monier, a French gardener, suggested that concrete reinforced with steel could be used for making sleepers for railway track.

Modern Permanent Way 2 Manchester Model Railway Society

line sleeper manufacture. They are 100 m and 200 m long. The output on these beds are: Standard and dual gauge sleepers • Stressing Bed 1 - 600 sleepers/day • Stressing Bed 2 - 296 sleepers/day Narrow gauge sleepers • Stressing Bed 1 - 720 sleepers/day • Stressing Bed 2 - 352 sleepers/day The Newman plant was purpose build to.

Railway Sleepers Their Types And Functions KPSTRUCTURES

Introduction Railway sleeper is a main component of railway track structure. Its function is to distribute loads from the rail foot to the underlying ballast bed. By passing train wheels the loads applied by the rail head will be in the form of impact loads.

Materials Free FullText A Numerical Study on Structural Performance of Railway Sleepers

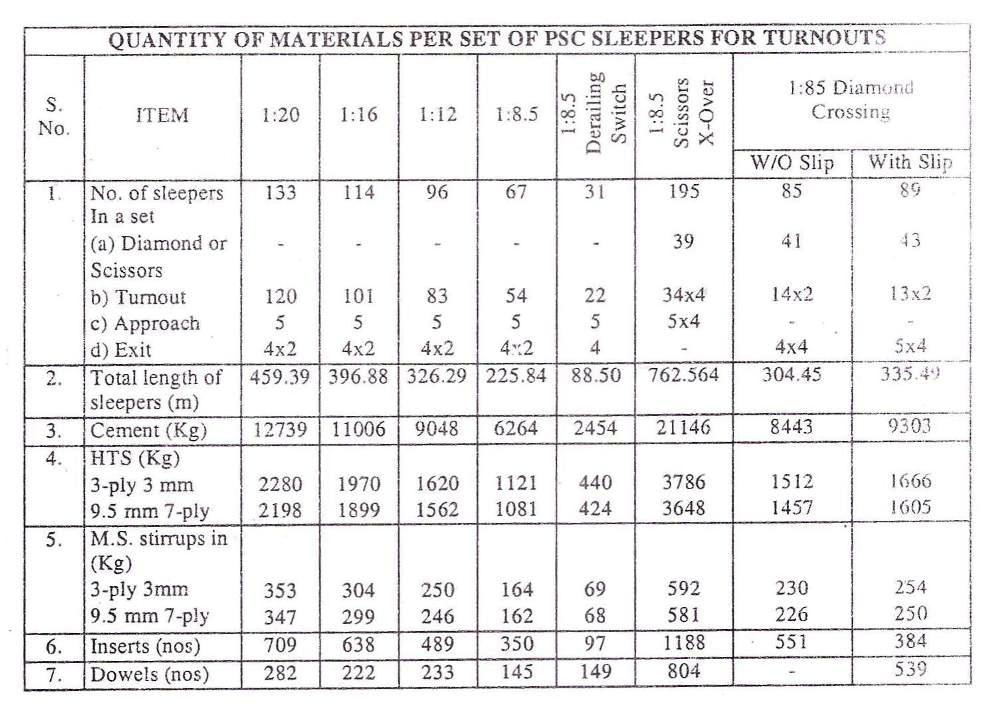

article Design of prestressed concrete sleepers 81 Posted: 28 July 2006 | | 5 comments The basis for design work for prestressed-concrete sleepers in Europe is EN 13230, valid since October 2002: "Concrete sleepers and bearers."

Prestressed concrete sleepers in Railway construction YouTube

The most common THICKNESS of railway sleepers is 125mm & 150mm. (5" & 6"). UK railway sleepers tend to be 125mm (5") & European railway sleepers 150mm (6"). Our selection of railway sleepers is now so varied that you will certainly find something that suits your plans and pocket.

Stack of concrete railway sleepers on the ground Stock Photo Alamy

1 Spacing of sleepers at non-welded rail joints should be adjusted locally as shown in the Table 2.1B. 2 New concrete sleepers in tracks carrying axle loads not exceeding 25 tonne when inserted in a face may be spaced at 667mm with a minimum of 10 sleepers per 6.67m and 1500/Km. This does not apply to low profile or interspersed concrete sleepers.

Sleepers Truman Chadwick

Benefits of Concrete Railway Sleepers. Concrete sleepers have many benefits over the use of traditional wooden sleepers. The most obvious is durability and longevity. Good quality precast concrete sleepers, like those we produce at Civilmart, will last 50 or more years. Additionally, our concrete sleepers are also:

Concrete Sleepers Patil Group

Sleepers Humes has over 50 years experience in the provision of prestressed and precast concrete railway sleepers for heavy haulage, mainline, secondary and high speed tracks across Australia. We provide a range of standard, dual and narrow gauge sleepers for applications including grain, electrical, transponder, pedestrian, transition and DED sleepers.

Stacks of Concrete Railway Sleepers at the Construction Site of a New Railway. Stock Photo

Concrete Sleepers - Design ETD-02-05 Introduction This document is uncontrolled when printed. Version Number: 1.1 Date Reviewed: 01 Jun 20 Page 3 of 12 1 Introduction 1.1 Purpose Provide design requirements for concrete sleepers supplied for use in Australian Rail Track Corporation track. 1.2 Scope

Concrete Railway Sleepers, Narrow, Rs 2600 /piece, Raghavendra Rail Lines Private Limited ID

Standard concrete sleepers are the components of your average retaining wall. They're usually 1.2 metres to 3 metres in length and include the following widths: 80mm, 100mm, 120mm and occasionally 150mm. Higher retaining walls require thicker and taller sleepers since they require additional reinforcement. Modular concrete sleepers have.

Regular concrete sleepers 1520 mm Concrete Sleeper Plant

1 Scope and Application This specification details requirements for the design and type approval of prestressed concrete sleepers complete with resilient fastenings and insulators for use in RailCorp track. Concrete sleepers for special applications, including multi-gauge tracks and turnout bearers, are not covered by this specification.